Minimize Downtime: Understanding the Fanuc Circuit Boards

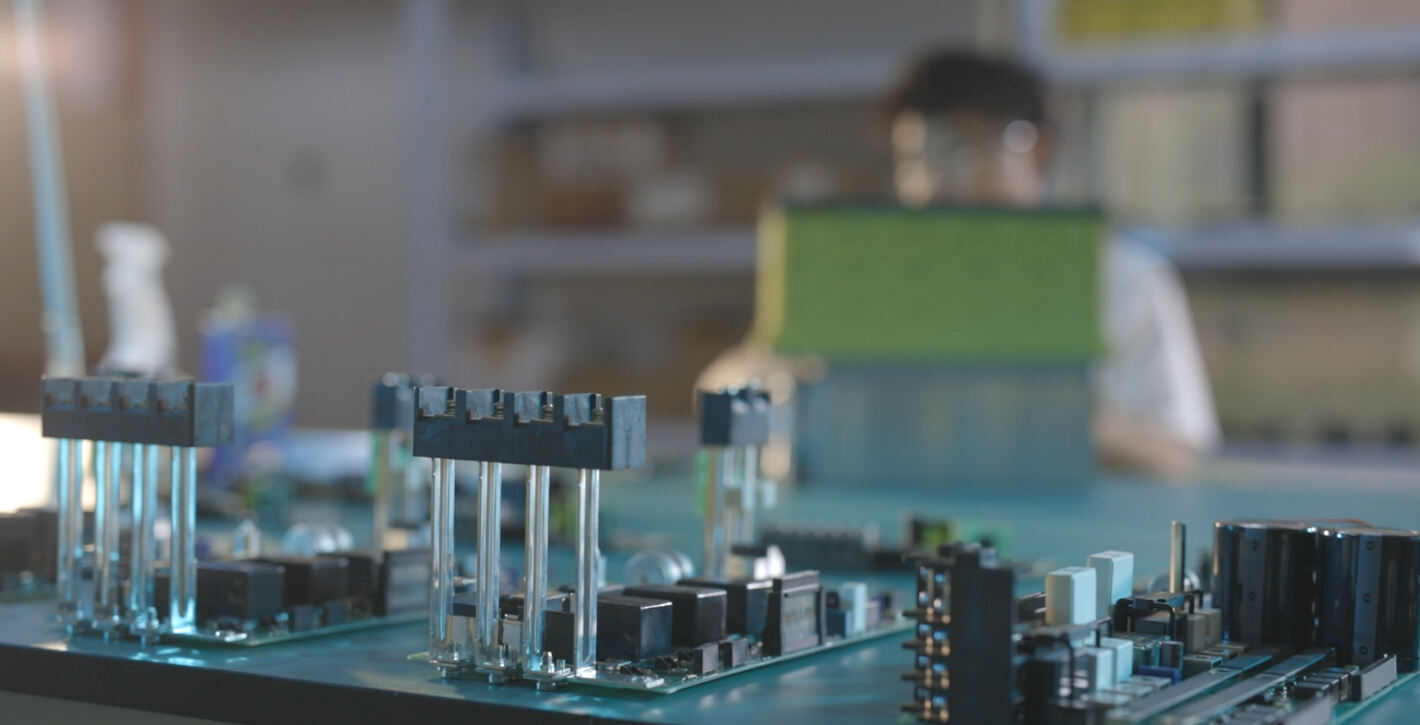

Do you understand Fanuc circuit boards? Understanding the various types of Fanuc circuit boards and their functions is critical to optimizing the performance of your CNC machine tool. By familiarizing yourself with Fanuc circuit boards, you can better understand the complexity and sophistication of your Fanuc system.

1. Brief Overview of Fanuc Boards

Fanuc circuit boards are an integral component of the Fanuc CNC machine tool control system. These boards are responsible for executing commands, processing data, and ensuring the smooth operation of the CNC machine.

2. Types of Fanuc Circuit Boards

- Main boards, processing and data exchange centers.

- Servo control boards, which handle the precise movement of machine axes.

- Input/output boards(IO boards), which manage the interaction between the CNC and external devices.

- Power boards, which ensure stable power supply to all components.

- Communication boards, facilitate data transfer between the CNC machine and other systems for seamless integration and automation.

3. Common Problems with Fanuc Boards

- Component failures are a major problem, because they can cause the CNC to malfunction or shut down completely. Critical components such as microprocessors, memory chips and connectors are particularly vulnerable.

- Connection problems (such as loose or damaged connections), can also affect communication between different parts of the CNC, resulting in erratic behavior or operational errors.

- Electrical faults, including power surges and short circuits, can cause serious damage to circuit boards. These failures can be caused by external factors such as power fluctuations or internal problems such as aging components.

4. Fanuc Circuit Board Repair and Replacement

When faced with a failing Fanuc circuit board, the decision to repair or replace it is a critical consideration. Repairing a circuit board can be a cost-effective solution, especially if there are minor problems or the board is relatively new. However, in cases of severe damage or extensive wear and tear, replacing the board may be a better option. This minimizes the risk of future failures.

5. Preventive Maintenance of Fanuc Boards

Routine inspections, to detect early signs of wear, damage, or failure.

Visual inspection, which can detect problems such as loose component connections, corrosion, or physical damage.

Electrical testing, which can detect faults or anomalies in the board's performance so that timely intervention can be made.

Regular cleaning, to keep Fanuc circuit boards clean and prevent the buildup of contaminants that can affect their function and cause overheating.

Summarize

That's why it's so important to understand and maintain Fanuc circuit boards. Reliable Fanuc parts and service can minimize downtime and ensure seamless CNC machine operation. Using genuine Fanuc parts from Songwei ensures that your equipment meets the highest standards of quality and performance.