Unlocking the Secrets Behind Fanuc Part Numbers

The world of CNC is complex, and understanding the intricacies of Fanuc part numbers is critical for anyone working with Fanuc systems. Fanuc, a leading brand in industrial automation, produces a wide range of CNC components, each of which is identified by a unique part number. These numbers are more than just random; they provide critical information about a part's function, compatibility and specifications. For anyone involved in the maintenance, repair or operation of a Fanuc system, knowing these part numbers is key to ensuring optimal performance and avoiding costly mistakes. This article will guide you through the meaning behind Fanuc part numbers, help you decipher their structure and make informed decisions when selecting or replacing components.

1. Decipher the Fanuc part numbers

Fanuc part numbers may seem complicated at first glance, but they can convey specific information. Typically, a Fanuc part number consists of several parts, each representing a different aspect of the part's identity. These parts may include a prefix, a core number, and sometimes a suffix or additional code.

Prefixes

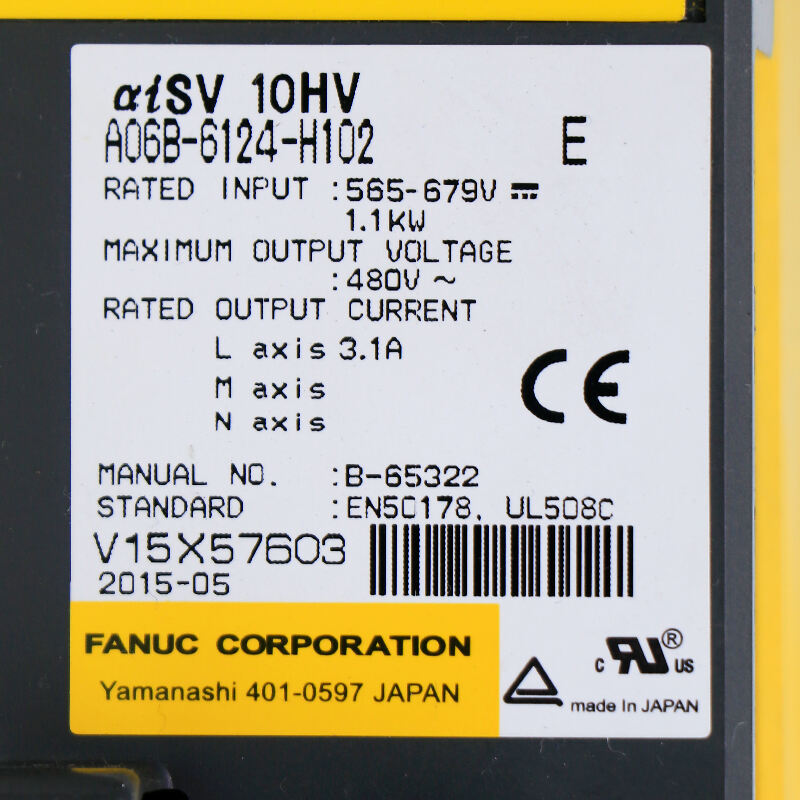

The prefix in a Fanuc part number is usually the first indicator of what the part is or where it is located in the wider system. Common prefixes such as "A06B", "A16B", or "A20B" are not just arbitrary codes; they indicate a specific type of part, such as a motor, drive, or amplifier. For example, "A06B" usually indicates a drive or motor, while "A16B" and "A20B" may refer to a PCB (printed circuit board) or other electronic component.

Core Numbers

At the heart of every Fanuc part number is the core number, which usually represents the specific model, generation, or series of the part. This core number is essential for identifying the exact specifications of a component, such as its power rating, size, or configuration. For example, in the "A06B" prefix category, different core numbers "0031", "0212" or "0266 " will distinguish between various servo motor or drive models, each designed for a different application or machine.

Suffixes or Additional Codes

In many Fanuc part numbers, a suffix or additional code may follow the core number to provide more detailed information about the function or variation of the part. These suffixes can indicate anything from a version or revision of the part to a specific configuration or customization. The part number may contain suffixes that indicate specific voltage ratings or unique connector types. For example, if "A06B" is the prefix and "B075" is the suffix, then this model number is usually a motor.

2. Examples of Common Fanuc Part Numbers

To illustrate the concepts discussed, we will analyze several real Fanuc part numbers, breaking down each part to reveal the full meaning behind the code. By examining examples from different categories, such as motors, drives, and encoders, you will gain a practical understanding of how to interpret these numbers. We'll compare parts with similar core numbers but different prefixes or suffixes, highlighting how these variations affect part application and compatibility. This hands-on approach will enhance your understanding and help you confidently decipher Fanuc part numbers in your own work. For example, here are a few examples.

Main Units (Controllers)

A02B-####-B###: This format typically represents main units or control boards. For example, A02B-0338-B520.

Servo/Spindle Drives

A06B-####-H###: This format denotes servo and spindle drives. For example, A06B-6124-H102.

Motors

A06B-####-B###: This format represents motors. For example, A06B-0148-B075.

Circuit Boards

A16B/A20B-####-####: This format generally represents circuit boards. For example, A16B-1212-0871 and A20B-2000-0170.

Encoders

A860-####-####: This format typically indicates encoders. For example, A860-2000-T301.

I/O Modules

A03B-####-C###: This format represents I/O modules. For example, A03B-0807-C001.

Conclusion

In conclusion, understanding Fanuc part numbers is an essential skill for anyone involved in the maintenance, repair, or operation of CNC machinery. These numbers provide critical insight into Fanuc component specifications and compatibility, helping you make informed decisions and avoid costly mistakes. By mastering the art of decoding Fanuc part numbers, you can ensure that your machines run at peak performance, minimize downtime and maximize efficiency. We encourage you to explore the resources and services offered by Songwei to further enhance your understanding and support your CNC needs.