Cum să scrii Fanuc PLC Ladder?

Comutatoarele Fanuc PLC joacă un rol esențial în sisteme care necesită un control precis și eficient, cum ar fi roboții din fabricarea auto sau mașinile CNC de fresaje din industria aerospațială. Capacitatea lor de a executa o logică complexă într-un format vizual simplu, cum ar fi diagramele de comutare, le face accesibile inginerilor și tehnicienilor fără cunoștințe extinse de programare. Acest articol se va concentra pe scrierea logicii de comutare Fanuc PLC pentru a vă oferi o înțelegere mai bună a Comutare Fanuc PLC .

1. Componentele de bază ale logicii de comutare Fanuc PLC

Tronsoane și contacte de comutare

Fiecare tronsoană în logica de comutare reprezintă o operațiune sau condiție specifică. Aceasta constă din două elemente cheie: contacte și bobine.

- Contacte: Asemanător cu comutatoare, ele reprezintă dispozitive de intrare (cum ar fi senzori sau butoane). Acestea pot fi fie „deschise normal” (NO) sau „închise normal” (NC). Contactele deschise normal permit curgerea curentului când intrarea corespunzătoare este PE (adevărat), în timp ce contactele închise normal permit curgerea curentului doar când intrarea este OFF (fals).

- Bobine: Bobinele reprezintă dispozitive de ieșire, cum ar fi motoare, luminile sau releurile. Bobina se activează (se aprinde) atunci când condiția rândului (adică contactul) este adevărată, ceea ce înseamnă că curentul curge prin rând.

Ieșiri și bobine

Într-un PLC Fanuc, ieșirile controlează dispozitive fizice precum electrovalvele, actuatorii și motoarele. Bobinele din logica schematică sunt folosite pentru a aceste dispozitive să se pornească sau oprească în funcție de condițiile de intrare. De exemplu, când un senzor detectează prezența unei părți, contactul de intrare corespunzător se închide și bobina energizează actuatorul pentru a ridica parte.

Releuri și timeri

- Releele funcționează ca comutatoare care controlează mai multe ieșiri dintr-o singură intrare sau condiție. Într-un sistem Fanuc, releele sunt utilizate pentru a se asigura că anumite operațiuni sunt executate doar după ce anumite condiții sunt îndeplinite, cum ar fi așteptarea unui semnal de la un senzor înainte de a porni un motor.

- Timerii ajută la controlul operațiunilor bazate pe timp, cum ar fi acțiuni întârziate sau periodice. De exemplu, TON (Timer cu întârziere la pornire) poate fi folosit pentru a aștepta 5 secunde după un semnal de pornire înainte de a porni motorul.

2. Ghid pas cu pas pentru scrierea logicii ladder pentru PLC-uri Fanuc

Pasul 1: Determinați procesul de control

Înainte de a scrie orice logică ladder, trebuie să înțelegeți profund procesul de control. Aveți în vedere tipul de mașinărie sau sistem pe care doriți să-l controlați - fie că este o mașină CNC, un bra robotic sau o linie de montaj. Identificați intrările cheie (senzori, comutatoare, etc.) și ieșirile (motoare, actuatoare, solenoide) implicate în proces.

De exemplu, într-o mașină CNC, intrările ar putea include senzori de poziție, schimbătoare de unelte și oprirea de urgență. Ieșirile ar putea fi motoarele care controlează spindle-ul, lichidul de răcire sau schimbătorul de unelte.

Pasul 2: Definirea Intrărilor și Ieșirilor

După înțelegerea procesului, următorul pas este să definiți clar toate intrările și ieșirile necesare. Într-un PLC Fanuc, fiecare dispozitiv de intrare/ieșire primește o adresă unică. Acest lucru este crucial pentru a asigura mapearea corectă a dispozitivelor într-un program de logică cu bare.

De exemplu

- Intrări: Comutatoare limite (X1, X2), senzori de apropiere (X3), oprire de urgență (X4).

- Ieșiri: Motor spindle (Y1), pompa de lichid de răcire (Y2), schimbător de unelte (Y3).

Pasul 3: Proiectarea Etapelor Logicii cu Bare

Proiectarea unei bare constă în crearea condițiilor logice care determină cum se activează ieșirile pe baza intrărilor. Pentru fiecare etapă, una sau mai multe intrări sunt de obicei evaluate înainte de activarea unei ieșiri. Aceste etape reprezintă secvența operațiunilor din fluxul de control.

De exemplu

- O etapă pentru pornirea motoarelor cu broaşă ar putea verifica că comutatoarele limită sunt libere (contacte deschise în mod normal) şi că oprirea de urgenţă este activă (contacte închise în mod normal).

- Dacă aceste condiţii sunt adevărate, bobina din bătătură este energizată şi motorul este pornit.

Etapa 4: Setarea releurilor, timer-urilor şi contorurilor

Releurile, timer-urile şi contorurile ajută la adăugarea funcţionalităţii logice. Timer-urile pot întârzi acţiunea (de exemplu, aşteptaţi 3 secunde înainte de a începe un motor), iar contorul poate ţine evidenţa numărului de piese produse sau cicluri finalizate. Releurile pot combina mai multe ieşiri pentru a controla mai multe ieşiri cu o singură intrare.

De exemplu

- Un timer TON poate întârzi începerea motoarelor cu broaşă până când se atinge o poziţie sigură.

- Un contor ţine evidenţa numărului de piese prelucrate şi activează un alarmă când se ajunge la un anumit număr.

Etapa 5: Testaţi logica cu schema electrică

După scrierea logicii în formă de scara, este timpul să o testați pe PLC Fanuc. Descărcați programul pe PLC și simulați condițiile de intrare. Observați cum se comportă ieșirea pentru a vă asigura că logica funcționează așa cum era prevăzut. Dacă PLC-ul produce erori sau rezultate ne dorite, utilizați instrumentele de diagnosticare pentru a depista problemele din logică.

3. Instrucțiuni Comune de Programare Logică în Formă de Scara pentru PLC-uri Fanuc

Instrucțiuni de Start și Stop

Instrucțiunile de start și stop sunt esențiale pentru controlul operațiunii mașinilor. De obicei, o instrucțiune de start declanșează pornirea unui generator sau actuator, în timp ce o instrucțiune de stop oprește operațiunea. De exemplu, apăsarea butonului de start energizează bobina pentru a porni motorul cu broască.

Comenzi Timer

Timer-ii controlează întârzierile operațiunilor. Există diferite tipuri de timer-uri în PLC-urile Fanuc:

- TON (Timer cu întârziere la pornire): activează ieșirea după o întârziere setată odată ce condiția de intrare este adevărată.

- TOF (Timer cu întârziere la oprire): oprește ieșirea după o întârziere odată ce condiția de intrare este falsă.

De exemplu, cronometrul TON întârzie pornirea motorului cu 5 secunde după ce un semnal de start este primit.

Comenzi de Contor

Contoarele urmăresc evenimente în timp, cum ar fi numărarea numerelor de piese produse, iar sistemele Fanuc PLC folosesc de regulă instrucțiunile CTU (numărare crescătoare) și CTD (numărare descrescătoare) în acest scop. Aceste instrucțiuni pot fi folosite pentru a declanșa o operațiune când se ajunge la un număr predefinit, cum ar fi pornirea unei alarme după ce au fost produse 100 de piese.

Instrucțiuni de Comparare

Sistemele Fanuc PLC folosesc instrucțiuni de comparare pentru a compara valorile de intrare cu limite predefinite sau alte valori. De exemplu, o valoare de intrare a unui senzor de temperatură poate fi comparată cu o prag predefinit pentru a activa un ventilator de răcire dacă temperatura depășește o anumită limită.

4. Depanare și Rezolvare a Problemelor în Logica Ladder Fanuc PLC

Erori Comune în Logica Ladder Fanuc PLC

Erorile în programarea logicii ladder pot fi cauzate de următoarele probleme:

- Poziție incorectă a contactului (deschis normal vs. închis normal).

- Adresele de intrare/ieșire lipsesc sau sunt incorecte.

- Bucla logică nu ajunge niciodată într-o stare „adevărată”, ceea ce determină inactivarea ieșirii.

Procedură de depanare a Logicii Ladder

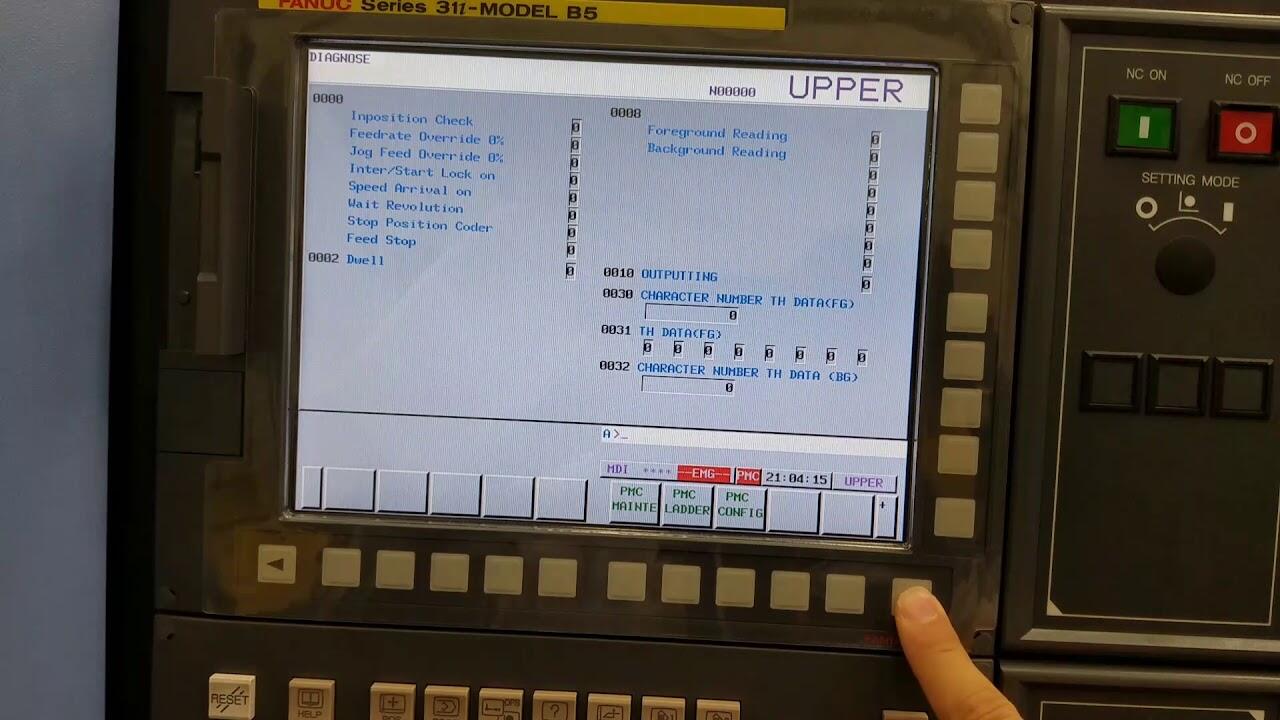

1) Verificați starea diagnostic a PLC-ului pentru eventuale alarme sau coduri de eroare specifice.

2) Isolați rulona problemă dezactivând celelalte ruloni și observând ieșirile. De exemplu, verificați dacă motorul se pornește singur fără condiții.

3) Utilizați software-ul de programare Fanuc pentru a simula intrările și ieșirile, asigurându-vă că sistemul reacționează așa cum este prevăzut.

Folosirea Unorilor de Diagnostica Fanuc PLC

Fanuc PLC oferă unelte de diagnosticare, cum ar fi jurnale de erori, afișaje ladder și mode test pentru a vă ajuta să localizați problemele. Puteți verifica comportamentul fiecărei ruloni ladder prin logica ladder sau puteți folosi uneltele de simulare pentru a testa diferite condiții de intrare fără a interacționa efectiv cu mașina.

5. Caracteristici Avansate ale Logicii Ladder Fanuc PLC

Tehnologia logică a scărilor avansată permite o flexibilitate și eficiență sporită, cum ar fi gestionarea controlului analog, secvențelor complexe și integrarea cu alte dispozitive.

- Intrări/ieșiri analogice: PLC-urile Fanuc pot manipula semnale analogice (cum ar fi senzori de temperatură), iar aceste intrări pot fi procesate folosind instrucțiuni specializate în logica scărilor.

- Comunicare: PLC-urile Fanuc pot comunica cu alte dispozitive folosind protocoale precum Ethernet/IP, Modbus sau Profibus, permițând integrarea cu alte sisteme precum SCADA sau module I/O la distanță.

Concluzie

În concluzie, redactarea unei logici clare și logice ale scărilor pentru PLC-urile Fanuc asigură o automatizare fără probleme, ceea ce duce la o creștere semnificativă a productivității. Dacă aveți întrebări, vă rugăm să contactați Songwei pentru servicii profesionale de programare Fanuc PLC sau formare.