7 Steps for Keeping Your Fanuc Motors in Top Shape!

Regular maintenance is critical to the life and performance of Fanuc motors. By investing time in routine maintenance, you can improve efficiency, reduce unplanned downtime and ensure reliable operation. This article provides essential tips to help you effectively maintain your Fanuc motors.

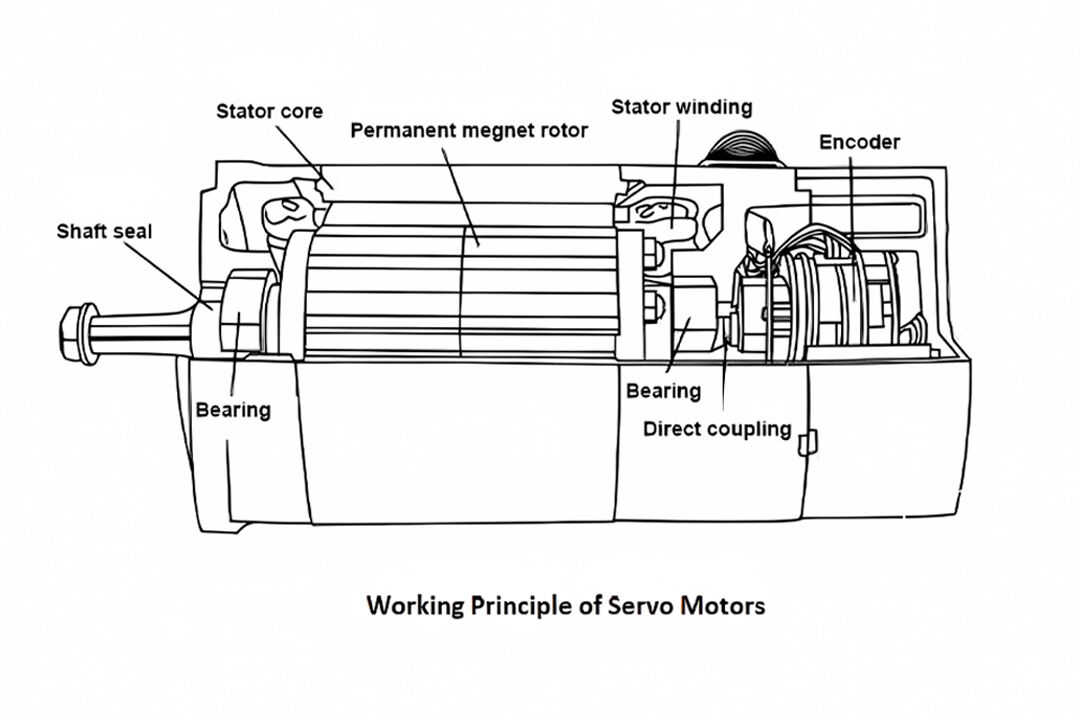

Understanding Your Fanuc Motors

Fanuc offers a variety of motor types, including AC, DC and servo motors. Each type has unique characteristics and applications. Key components of a typical motor include the stator, rotor, and encoder. To better maintain your motor, understand the role each component plays in overall motor performance.

How to maintain your motor

1. Develop a maintenance program

Develop a maintenance schedule that identifies how often each maintenance task should be performed - daily, weekly, monthly or quarterly. Use checklists to ensure that all necessary tasks such as inspections, lubrication, and testing are completed, making it easier to track the health of your motor.

2. Clean Fanuc motors

Dust and debris can hinder motor performance. Regular cleaning helps prevent overheating and wear. Use compressed air and a soft brush to gently remove dirt from external and internal components. Avoid the use of harsh chemicals that can damage sensitive parts to ensure a safe and effective cleaning process.

3. Inspect and replace bearings

Check for signs of wear including abnormal noise, vibration or overheating. Regularly inspect the bearings for signs of damage and replace them as needed to maintain optimum performance. The following can be referred to regarding the replacement of Fanuc spindle motor bearings:

- The spindle motor bearings are precision workpieces, and the disassembly force should not act directly on the ball of the bearings or on the outer ring, i.e., when disassembling and assembling the bearings on the spindle, the force should act on the inner ring of the bearings, so as not to reduce the precision of the bearings and affect their life.

- Assembly bearings, angular contact bearings should ensure and disassembly when the configuration is the same (note: bearing inner ring or outer ring end face of one side is wide, the other side is narrow, do not install the wrong, otherwise it will cause the inner and outer ring separation, the spindle radial runout lei, bearings are easy to damage)

- Spindle motor regular replacement of grease, grease for special high-speed lithium grease.

- Spindle motor operation found in the sound or vibration abnormalities, should be stopped to check the bearings, is not damaged, if necessary, replace the new bearings, operation issued by the abnormal odours or shutdown cut off the power supply, to megawatt meter insert motor stator resistance, such as resistance of 0 for burned out, should be replaced with a stator coil.

- Cleaning bearings when the first 93 # standard immersion 15 minutes, with a brush brush laundry, each time the application of clean cleaning more than three times, it is strictly prohibited to rotate in the absence of clean, to be dried plus high-speed lithium grease, grease filling amount of about 20% -50% of the bearing space.

4. Check electrical connections

Periodically check all connections for signs of corrosion, wear or looseness. Tighten any loose connections and remove corrosion with a suitable electrical contact cleaner.

5. Monitor motor temperature

Temperature fluctuations can seriously affect motor performance. Use a thermal sensor to regularly monitor the motor's operating temperature. Ensure that the cooling system is functioning properly to prevent overheating. If temperatures exceed recommended levels, investigate potential causes and take corrective action.

6. Lubrication measures

Proper lubrication reduces friction and wear on Fanuc motors. Use the manufacturer's recommended lubricant and observe proper usage. Avoid excessive lubrication, which attracts dirt and causes additional wear. Develop a lubrication program to track when and where lubrication is applied.

7. Test motor performance

Routine performance tests can detect problems before they escalate. Perform tests such as vibration analysis, electrical testing, and load testing to evaluate motor function. Record test results and track performance trends over time to help identify potential problems early.

Conclusion

In conclusion, maintaining Fanuc motors is critical to ensuring their efficiency and reliability. By implementing a proactive maintenance strategy and following the tips outlined in this article, you can extend the life of your motors and improve overall operating performance. Use these methods to get the best results and minimize costly downtime. For expert assistance with maintenance or repairs, please feel free to contact our team at Songwei!