Unlocking Precision: The Inner Workings of a Fanuc Servo Drive

Fanuc servo drives are an essential part of modern automation and CNC machinery. These drives convert commands into precise motion, which ensures that machinery operates with high precision and efficiency. As a leading brand in the field of industrial automation, Fanuc's servo drives are known for their reliability and advanced technology, making them the first choice for many manufacturers. So do you understand how Fanuc drives operate?

Fanuc servo drive operation

Servo drives are specialized electronic devices that control the movement of motors. They receive input commands and translate them into precise motor movements, while providing feedback to ensure accuracy. Servo drives use continuous feedback to achieve smooth and precise motion. As a result, servo drives are ideally suited for applications that require high precision and dynamic performance.

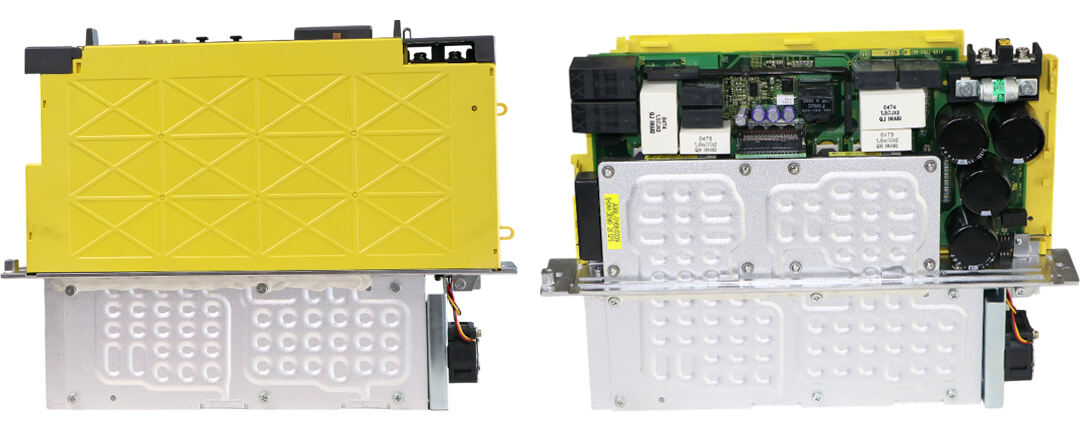

1. Internal Structure of Fanuc Servo Drives

Control Circuit Board : Processes incoming commands from the CNC controller and interprets these commands to regulate motor movements.

Feedback Device : Monitors the position and speed of the motor using encoders and sensors to ensure that the system can make real-time adjustments.

The seamless interaction between the power supply, control circuitry, and feedback device enables Fanuc servo drives to provide excellent performance in demanding applications.

2. How Servo Drives Work

Description of Closed-Loop Control: Fanuc servo drives operate on a closed-loop control system, where the drive continuously monitors the position and speed of the motor through a feedback mechanism.

How commands are received and processed: Commands from the CNC controller are converted into electrical signals that instruct the servo drive how to move the motor.

The Role of Feedback in Achieving Precise Motion: Feedback devices constantly report the actual position of the motor to the control circuitry so that adjustments can be made in real time to maintain accuracy.

3. Control Algorithms and Communications Used in Fanuc Servo Drives

Fanuc servo drives utilize a variety of control algorithms, such as Proportional-Integral-Differential (PID) control, to ensure precise motion.

Correctly adjusting these parameters minimizes errors, reduces overshoot, and improves the overall responsiveness of the system.Fanuc servo drives utilize a variety of communication protocols, such as CANopen and EtherCAT, to facilitate the exchange of data between the drives and CNC controllers. These protocols enable fast communication, allowing the servo drive to respond instantly to changes in operating conditions.

Fanuc Servo Drives Applications

Fanuc servo drives are used in a wide range of industries, including automotive, aerospace and electronics manufacturing. They are indispensable in robotics, CNC milling and other automated processes.

Benefits of using Fanuc Servo Drives: These drives are highly valuable in modern manufacturing environments because they increase productivity, improve accuracy, and reduce downtime.

Conclusion

A thorough understanding of how Fanuc servo drives work goes a long way toward optimizing your CNC system and ensuring smooth operation. If you have needs when optimizing your Fanuc system you are welcome to consult an expert for personalized support to ensure long-term success and productivity.