Fanuc motorlaringizni eng yaxshi holatda saqlash uchun 7 qadam!

Regulyar muhofaza Fanuc motorlari yashasi va ishlash holati uchun muhim. Routin muhofazaga vaqt sarflash orqali siz effeksiyani oshirish, noma'lum to'xtashni kamaytirish va ishlangan operatsiyani ta'minlash uchun imkoniyatga ega bo'lasiz. Ushbu maqola sizning Fanuc motorlaringizni effektiv ravishda muhofazalashga yordam beradigan asosiy maslahatlarni taqdim etadi.

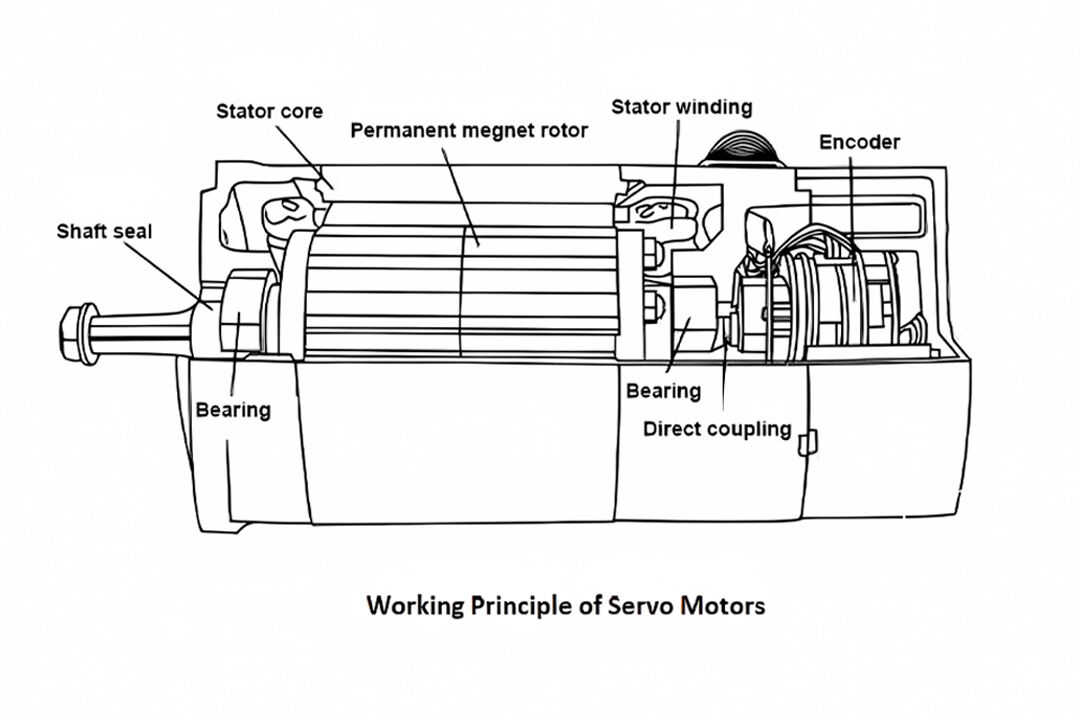

Fanuc Motorlaringizni tushunish

Fanuc turli xil motorturkimi taklif qiladi, shu jumladan AC, DC va servomotorlar. Har bir turgina xususiyatlari va qo'llanishi mavjud. Tipik motor asosiy qismlari sator, rotor va encoderdan iborat. Motoringizni yaxshi muhofazalash uchun har bir komponentning umumiy motor performansida qanday rol o'ynaydiganini tushunishingiz kerak.

Motoringizni qanday muhofazalash kerak

1. Muhofaza dasturini yarating

Kunlik, haftlik, oylik yoki kvartallik ravishda qanday turdagi texnik xizmat ko'rsatilishi kerakligini aniqlaydigan texnik xizmat jadvalini tuzing. Tekshiruvlar, masalan, tekshiruv, sharmlash va sinov kabi barcha zarur vazifalarning bajaringanligiga ishonch hosil qilish uchun ro'yxatdan foydalaning, shuningdek, elektr motoringizning holatini kuzatishni osonroq qiling.

2. Fanuc motorlarini tozalash

Tozalar va qotirlar motor performansini past qishtirishi mumkin. Regulyar tozalash overdam va auslanishni oldini olishga yordam beradi. Tashqi va ichki komponentlardan qotirlingizni noqulay usulda olib tashlash uchun surkatchali havo va yumshoq burchni ishlatishingiz mumkin. Sharhli qismlarni ayb etish uchun qattiq himoya asarlardan foydalanmang, bunday holatda mos va effektiv tozalash jarayonini ta'minlash mumkin bo'ladi.

3. Sharmlarni tekshirib ko'rish va almashtirish

Ovvoz, siljish yoki overdam belgilari borligini tekshiring. Optimal performansni saqlash uchun sharmlarni ayb bilan bog'liq belgilar bo'yicha regulyar ravishda tekshiring va qayerda kerak bo'lsa ularni almashtiring. Fanuc spindel motor sharmlarini almashtirishga doir quyidagilarga murojaat qilish mumkin:

- Vosita motorining qurxantalari to‘g‘ri ishlab chiqarilgan ish materiallari hisoblanadi, va vosita qurxantalaridan yoki tashqi aylanaidan chiqarish kuchi to‘g‘ri ravishda amal qilishi kerak emas, ya'ni vosita qurxantalari to‘g‘ri ravishda amal qilishi uchun ichki aylanaga asoslangan bo‘lishi kerak, shuning uchun vosita qurxantalari tomonidan amal qilingan aniqlilik kamaymaydi va ularning miqdori uzaydi.

- Qurxantalarni to‘g‘ri ravishda o‘rnatish uchun, burchakli kontaktli qurxantalarda o‘rnatish va chiqarish konfiguratsiyasi bir xil bo‘lishi lozim (eslatma: qurxantaning ichki yoki tashqi aylanasi tomonidan yopilgan yuzi bir tomondan keng, ikkinchi tomondan esa quyosh, noto‘g‘ri o‘rnatingan holda ichki va tashqi aylanalar ajratiladi, vosita radial ravishda ajratiladi, qurxantalarning muddati yakunlanadi)

- Vosita motorini regulyar ravishda almashtiring yogʻ , maxsus tezlikdagi litovskiy mas.

- Asosiy motor ishlatilishi va sestan yoki titrimlarni anormalliklarni aniqlash uchun to'xtatish kerak, shuningdek, yorug'liklar bo'lmaganiga tekshirish kerak, agar kerak bo'lsa, yangi yorug'liklarni almashtiring, ishga tushirishda anormal bukimi yoki qo'shimcha kutilgan bo'lsa, to'qishni o'chirib tashlang, megavat metrga motor statorni elektrik muqovasi kirgizilsin, masalan, muqova 0 bo'lsa, yangi statorda almashtirish kerak.

- Yorug'liklarni tozalashda birinchi marta 93 # standart orqali 15 daqiqa ichida tozalovchi suvda tozalaydi, shu keyinchalik bursh bilan tozalaydi, har bir marta tozalashdan keyin tozalash uchun eng kamida uch marta toza suv qo'llab chiqaradi, tozalangan holda aylantirish taqiqlangan, ushbu yorug'liklarni ushlab qolganidan so'ng baland tezlikdagi litium greytasini qo'shing, greytaning to'ldirilishi yorug'likning jami joyining %20-%50 ga teng bo'lishi kerak.

4. Elektrik aloqalarini tekshiring

Korrupsiya, xatosi yoki yoyilganligi belgisini ko'rsatadigan barcha aloqalarni davom etish orqali tekshiring. Yoyilgan barcha aloqalarni mos keladigan elektrik kontakt tozalovchisi bilan tozalab chiqaring.

5. Motor temperaturini kuzatib boring

Температура айирбашлари моторнинг ишлашига келисиз таъсир этishi мумкин. Моторнинг ишlashi температурасини муодида кузатиш учун термал сенсордан фойдаланинг. Куватлиш тизими йориқ фаолиятida бўlishini таъминлашингиз керак, chunk ушбу тизим озича топишдан сонг. Агар температура рекомендованный деңгизлардан юксак бўлса, шундай холатнинг сабабини aniqlang va керакли ҳароқатларни амалга ошинг.

6. Тушқинчилик ҳамда маслахатлари

Тушқинчилик тизими туғри равишда ишлатилганда Фанук моторларидаги чирчиллик ва износ камайтирилади. Ишlab чиқарувчи тушқинчилик материалини тавсия этиш ва унинг туғри равишда ишлатилиши керак. Кўп турли тушқинчилик материаллари пыртақларга ўзини беради ва кўпроқ износга себеп бўлади. Тушқинчилик тизими яратиш учун келасиз ва унинг кайси жойларида ва кай вақтда ишлатилганлигини кузатиш учун дастур яратинг.

7. Моторни синовlash Ishlash

Рутин тестлари муаммолар эскалациялашidan oldin ularga келиш мумкин. Мотор функциясини баҳолаш учун ҳаракат таҳлили, электрик тестлари ва юк тестлари кabi тестларни амалга ошинг. Тест натижаларини ёзиб тутинг ва вақт даврида бажарилган тестлар натижаларини кузатишингиз билан потенциал муаммоларни биринчи вақтда aniqlashingiz mumkin.

Xulosa

Nihoyatda, Fanuc motorlarni saqlash ularning effektivligini va ishonchli ishlashini ta'minlash uchun muhim. Maqolada berilgan tavsiyalarni amalga oshirib, oldindan davom etuvchi xizmat ko'rsatish strategiyasini ijro etishingiz orqali motorlarining hayot muddatini uzaytirishingiz va umumiy ishlangan performansni yaxshilashingiz mumkin. Eng yaxshi natijalarni olish va qimmat bo'lgan to'xtashlardan oldini olish uchun bu usullardan foydalaning. Xizmat ko'rsatish yoki tuzatish bilan bog'liq muammolar bo'yicha mutaxassis yordam kerak bo'lsa, iltimos, bizning jamoa Songwei-da bog'laning!