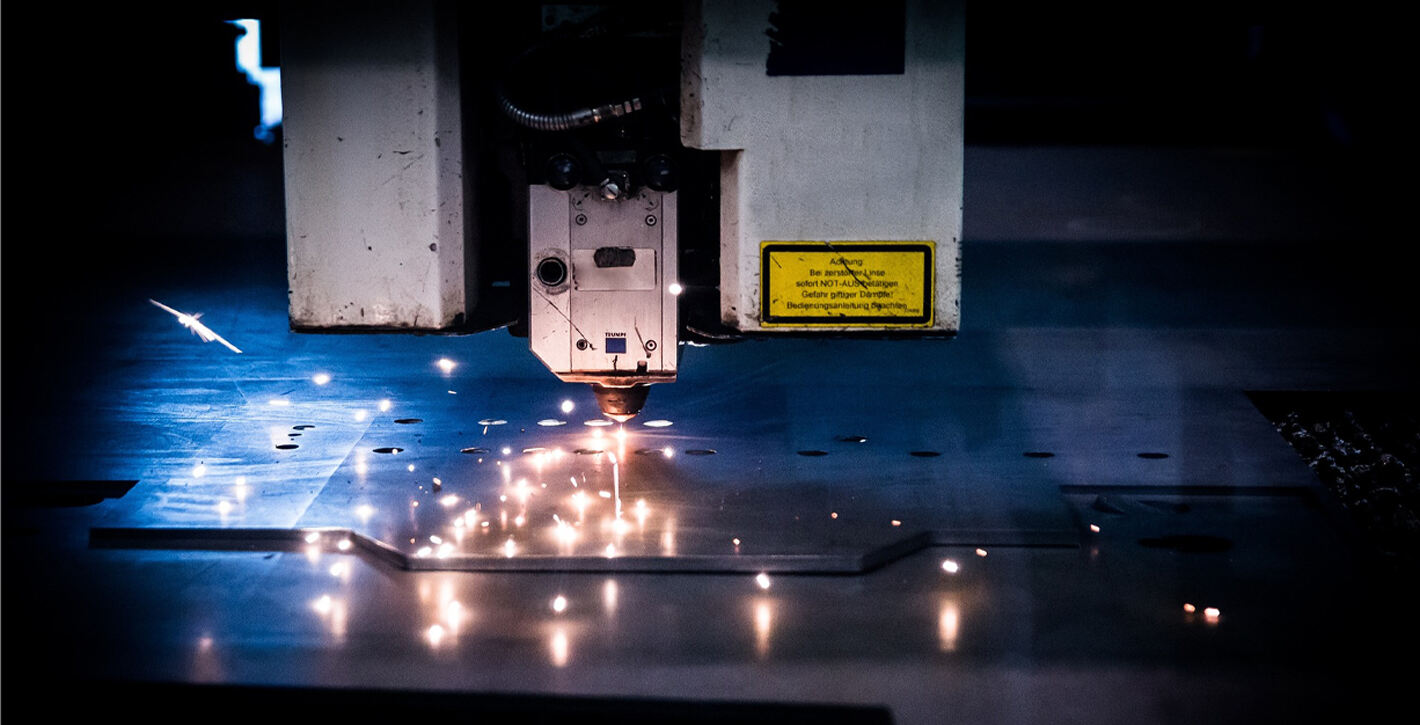

Kurangi Waktu Downtime: Panduan Esensial untuk Menjaga Mesin CNC-mu Berjalan dengan Songwei

Dina jagat otomasi industri jeung operasi CNC, waktosong mangrupa isu kritisis nu bisa ngaruh buruk kana produktifitas sarta laba. Pikeun perusahaan anu ngandalkan bagian-bagian CNC Fanuc, ngerti jeung ngurangkeun waktosong geus penting pikeun nyokot posisi kompetitif. Dina artikel ieu, Songwei ngalor-ngidul kana aspek-aspek waktosong, salaku definisi, sebab-sebab, dampak finansial, dlsb., sarta ngahargaan khusus kana pentingna pikeun ngagunaan bagian sarta jasa anu terpercaya. FANUC bagian sarta jasa.

Definisi Waktosong

Waktosong nyaeta sakumaha waktu sahente alat atawa mesin teu ngoperasi produksi. Ieu bisa nyertikeun situasi anu mana mesin sedeng diwatesan, dirawat, atawa teu ngoperasi akibat gangguan atawa masalah lianna.

Sebab umum waktosong

-

Waktosong ancur-ancuran:

Pemeliharaan rutin.

Pambaruan atawa upgrade perangkat lunak.

- Waktosong teu direncanakeun:

Kegagalan jeung gangguan peralatan.

Kurangna pemeliharaan teratur.

Salah tangan kaunan jeung kesalahan operasional.

Gangguan rantai pasok jeung kurangna bagian.

Masalah jeung perybaran lunjuk lunak.

Dampak Finansial Tépi Waktosapten

Biaya langsung: produksi hilang, biaya tenaga kerja, lembur jeung pemeliharaan.

Biaya tak langsung: ketidaksukaan pelanggan, kehilangan pelanggan potensial jeung rusakna reputasi merek.

Biaya opurtuniti: kehilangan pendapatan potensial jeung tunda proyek.

Mengitung Biaya Waktosapten

Panduan langkah demi langkah cara ngitung biaya downtime.

Tentukan biaya per jam operasi.

Tentukan rata-rata downtime.

Hitung total biaya pikeun ngagunakeun rumus sarta conto.

Strategi kanggo Minimisasi Downtime

Laksanakan pemeliharaan lan inspeksi reguler.

Colongan dina spare part Fanuc boga kualitas tinggi sarta terpercaya.

Gunakeun teknik pemeliharaan prediktif.

Latihankeun karyawan sarta ngaresepkeun prosedur operasi.

Bentuk supply chain kang goleh dipercaya sarta simpen bagian spare parts penting di stok.

Peran Penting Bagian Fanuc yang Andal dan Layanan

Bagian Fanuc yang andal dan layanan memainkan peran penting dalam meminimalkan waktu pemadaman dan memastikan operasi lancar alat mesin CNC. Frekuensi dan durasi pemadaman yang direncanakan dan tidak direncanakan dapat dikurangi secara signifikan dengan menggunakan bagian Fanuc asli berkualitas tinggi dari pemasok terpercaya seperti Songwei. Berikut caranya:

- Peningkatan kinerja dan umur panjang: Bagian Fanuc asli dirancang untuk memenuhi standar kualitas dan kinerja tertinggi.

- Kesesuaian dan Integrasi: Menggunakan bagian Fanuc asli memastikan kesesuaian penuh dengan peralatan yang ada.

- Pengujian dan sertifikasi menyeluruh: Komponen Songwei mengalami proses pengujian dan sertifikasi menyeluruh.

- Perawatan dan Dukungan Ahli: Akses ke layanan perawatan dan dukungan ahli sangat penting untuk mencegah dan menyelesaikan masalah pemadaman, dan Songwei menawarkan layanan perawatan khusus yang dilakukan oleh teknisi berpengalaman yang mahir dalam sistem Fanuc.

- Peningkatan dan pemodernan: Meningkatkan dan memodernisasi peralatan Anda dengan komponen Fanuc terbaru dapat meningkatkan kinerja dan keandalan.

Kasimpulan

Secara keseluruhan, menyelesaikan masalah downtime memerlukan langkah-langkah yang mencakup pemeliharaan pencegahan, suku cadang berkualitas, dan dukungan ahli untuk meminimalkan downtime dan mengoptimalkan operasi.

Suku cadang dan layanan Fanuc yang andal merupakan bagian integral dari solusi masalah downtime, dan suku cadang berkualitas serta jasa pemeliharaan ahli dari Songwei memastikan bahwa mesin CNC Anda beroperasi dengan efisiensi maksimal dan meminimalkan downtime. Dengan bekerja sama dengan penyedia terpercaya , Anda dapat meningkatkan kinerja dan umur peralatan Anda, yang menghasilkan peningkatan produktivitas dan keuntungan.