7 Langkah Pikeun Ngejaga Motor Fanuc Agar Selalu Dina!

Pangrawatan rutin anu penting pikeun umur sarta kapadetan motor Fanuc. Dengan ngabogaan waktosakum pikeun pangrawatan rutin, sampeurna bisa nambahkeun kapadetan, ngurangkeun waktu beurat nu teu direncanakeun sarta ngajamin oparasikeun anu terpecaya. Artikel ieu ngasuplai tips penting pikeun bantu sampeurna pangrawatkeun motor Fanuc sampeyan.

Mengerti Motor Fanuc Sampeyan

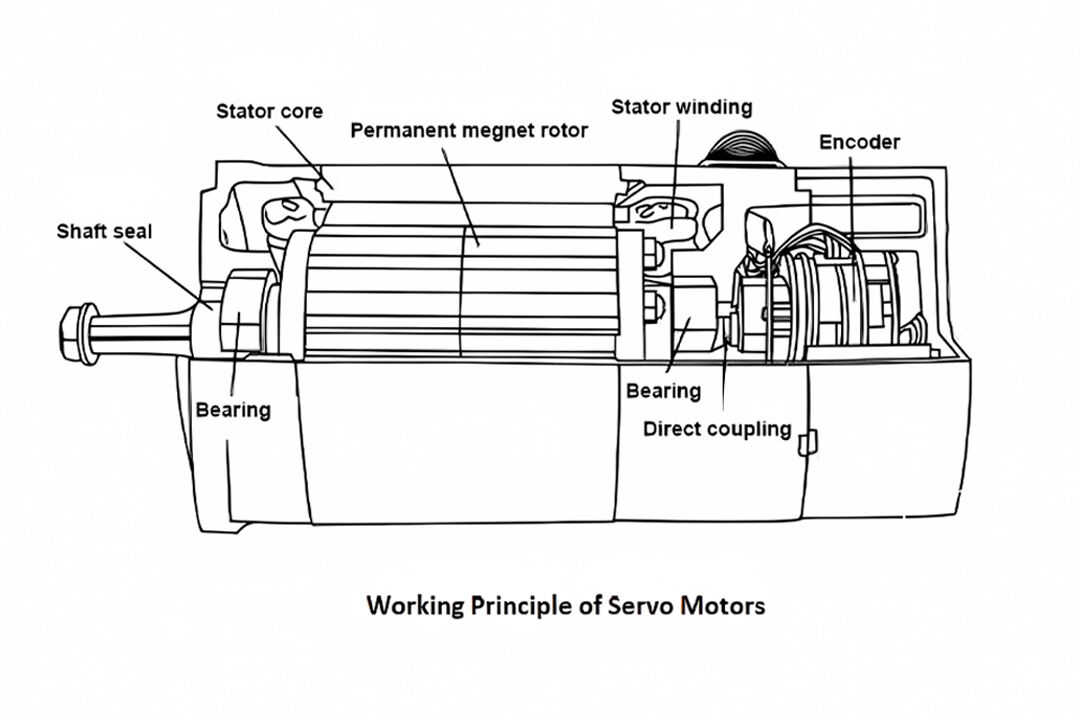

Fanuc ngahasilkeun bermacam-jenis tipe motor, jero kana AC, DC sarta motor servo. Tiap tipe ogé karatina sarta aplikasi anu unik. Komponen utama tina motor biasa nyaeta stator, rotor, sarta encoder. Pikeun leuwih pangrawatkeun motor sampeyan, ngarti keur ngarti peran ti setiap komponen dina kapadetan motor kabehna.

Kagimana pangrawatkeun motor sampeyan

1. Buat program pangrawatan

Kembangkeun jadwal pameyeuh anu ngajelaskeun seujak sabaraha kal tungtung pameyeuhna perlu dilakukeun - harian, mingguan, bulanan atawa kuartalan. Gunakeun daftar periksa supadoséna sareng kabéh tugas anu diperlukan kaya inspeksi, pelumasan, sareng uji téh dilakukeun, nyaeta gampang nyieun motor anjeun diawasi kesehatanna.

2. Bersihkeun motor Fanuc

Debu sareng sampah bisa ngaru keur kapacitan motor. Pembersihan reguler ngebantu mencegah panas leuwih sareng aus. Gunakeun angin terkompresi sareng sikat lembut pikeun ngahilangkan tanah tina komponén éksternal sareng internal. Hindari pikeun ngagunakeun bahan kimia kasar anu bisa merusak bagian sensitif pikeun nepatkeun prosés pembersihan anu aman sareng efektif.

3. Periksalah sareng gantilah béaring

Periksalah tanda-tanda aus kayana suara aneh, getaran, atawa panas leuwih. Periksalah béaring sakumna tanda-tanda rusak sareng gantilahna saiki butuh pikeun ngeunaan kapacitan optimum. Éta bisa dirujuk ngeunaan penggantian béaring motor poros Fanuc:

- Bearing motor spindel nyaéta karya presisi, jeung gaya disasembli tina ball bearing atawa ring luar teu bisa ngaruh sarana langsung, anu artina pas disasembli jeung diasembli, gaya kudu ngaruh kana ring dalem bearing supaya presisi bearing teu turun sarta umurna teu terpengaruh.

- Dumasar bearing, bearing kontak angular kudu dipastikeun kalau konfigurasi dumasar jeung disasembli sarua (catetan: sisi hiji sisi ring dalem atawa ring luara lebar, sisi lianna cicing, jangan kasebut, lamun salah geus ngebulatkeun ring dalem sarta luara, spindle bakal ngalami runout radial, bearing gampang rusak)

- Motor spindel diganti secara reguler lemak , lemak khusus lithium kecepatan tinggi.

- Operasi motor pusingan ngalami suara atawa getaran aneh, katuhu dihentikan pikeun nyheck bering, teu rosak, lamun perlu, ganti bering anyar, operasi ngahasilkeun bau aneh atawa mati, putuskeun pasokan listrik, Pikeun megawe meter insert tahanan stator motor, salaku conto, tahanan 0 pikeun bakar, katuhu diganti jeung koil stator.

- Ngalepas bering kala awal 93 # standar imerse 15 menit, ngagunkan sikat pikeun ngalepas cucian, tiap kali aplikasi bersih cucian leuwih tibat saka tilu kali, anu teu dibolehkeun pikeun puter dina keadaan teu bersih, pikeun dikeringkeun tambah grease litium kencang, jumlah pengisian grease ngeunaan 20% -50% tina ruang bering.

4. Periksa koneksi listrik

Periksa sakumput koneksi secara berkala Pikeun tanda-tanda korosi, aus atawa longgar. Kencengkeun koneksi anu longgar jeung lepasin korosi jeung pembersih kontak listrik anu sesuai.

5. Awasi temperatur motor

Fluktuasi suhu bisa ngaruh serius kana kapasitas motor. Gunakan sensor termal pikeun pangawasan teratur suhu operasi motor. Pastikean sistim cooling fungsi bener pikeun mencegah keleuwihan panas. Kalau suhu leuwih tina batas anjuran, cari sebabna jeung ambil tindakan perbaikan.

6. Ukuran pelumatan

Pelumatan anu tepat ngurangkeun gesekan sarta aus dina motor Fanuc. Gunakan pelumas anu direkomendasikeun pabrik jeung patuhkeun cara pemakaiannya. Hindari pelumatan berlebihan anu ngecapet kotoran sarta nyebabkeun aus tambahan. Bangun program pelumatan pikeun nyieun kapan sarta dimana pelumatan dipaké.

7. Uji motor PERFORMA

Pengujian rutin bisa ngedeteksi masalah sebelum marikasa. Lakukeun uji kaya analisis getaran, uji listrik, sarta uji beban pikeun nyarios nilai fungsi motor. Catet hasil uji sarta lacak tren performa dina waktu pikeun nolong ngidentifikasi masalah potensial di awal.

Kasimpulan

Dina sumbangan, ngajaga motor Fanuc mangrupa hal anu kritisan pikeun ngajamin efisiensi sarta kepercayaanana. Dumasar kana strategi pemeliharaan proaktif sarta ngikuti tip-tip anu disebutkeun dina artikel ieu, sampean bisa ngeprakkeun umur motor anjeun sarta ngarengkatkeun kapaduan operasi gumantungan. Gunakan metoda ieu pikeun nyieun hasil anu terbaik sarta ngurangkeun waktu beureum anu mahal. Pikeun bantuan ahli dina pemeliharaan atawa perbaikan, haturkan kasihan hubungi Tim Kami di Songwei!