Reduce Downtime: The Essential Guide to Keeping Your CNC Machines Running with Songwei

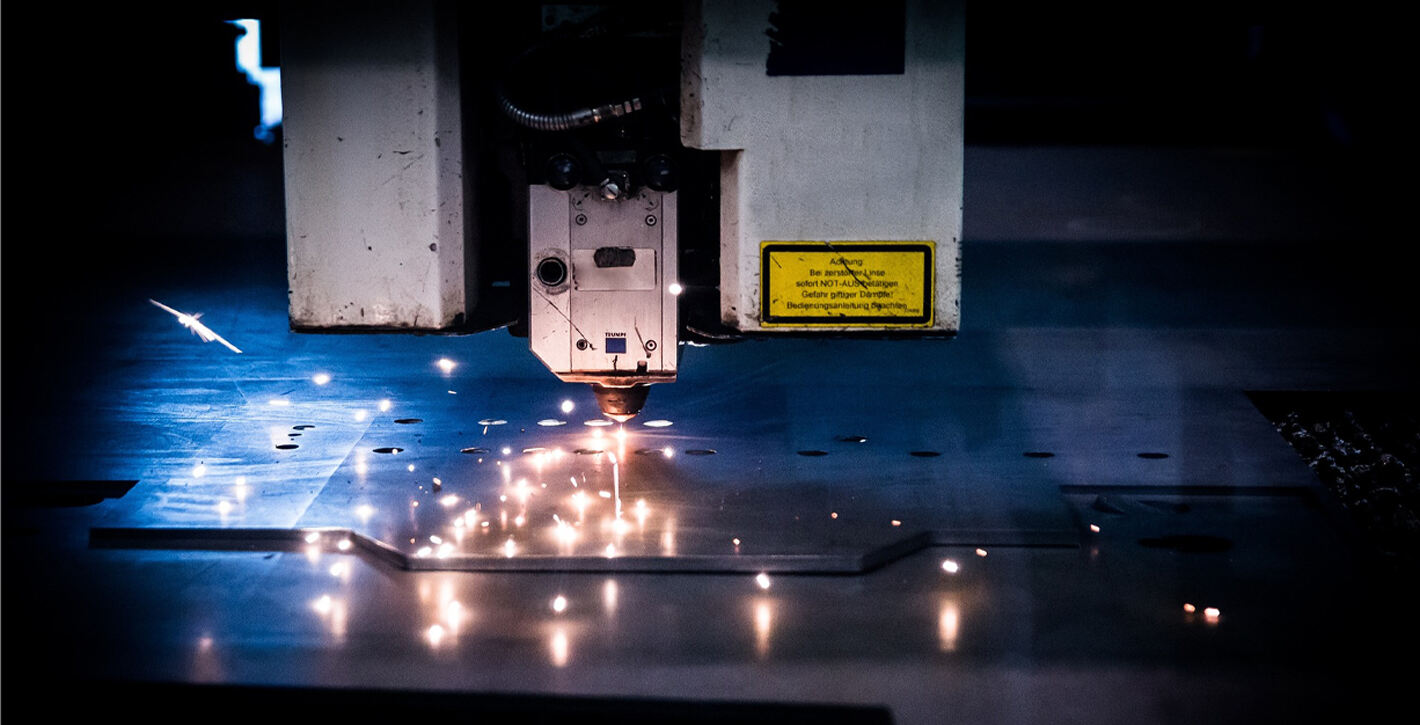

In the world of industrial automation and CNC operations, downtime is a critical issue that can severely impact productivity and profitability. For companies that rely on Fanuc CNC parts, understanding and minimizing downtime is critical to maintaining a competitive edge. In this article, Songwei explores various aspects of downtime, including its definition, causes, financial impact, etc., and specifically emphasizes the importance of using reliable Fanuc parts and services.

Definition of Downtime

Downtime is any period of time when equipment or machinery is not in productive operation. This may include situations where a machine is undergoing repair, maintenance, or is not operating due to a malfunction or other problem.

Common Causes of Downtime

-

Planned downtime:

Routine maintenance.

Software updates or upgrades.

- Unplanned downtime:

Equipment failures and malfunctions.

Lack of regular maintenance.

Human error and operational mistakes.

Supply chain disruptions and parts shortages.

Software problems and updates.

Financial Impact of Downtime

Direct costs: lost production, labor costs, overtime and maintenance.

Indirect costs: customer dissatisfaction, loss of potential customers and damage to brand reputation.

Opportunity costs: loss of potential revenue and project delays.

Calculating Downtime Costs

Step-by-step guide on how to calculate downtime costs.

Determine the cost per hour of operation.

Determine the average downtime.

Calculate total cost using relevant formulas and examples.

Strategies to Minimize Downtime

Perform regular maintenance and inspections.

Invest in high-quality, reliable Fanuc parts.

Use predictive maintenance techniques.

Train employees and improve operating procedures.

Establish a robust supply chain and keep critical spare parts in stock.

The Role of Reliable Fanuc Parts and Services

Reliable Fanuc parts and service play a vital role in minimizing downtime and ensuring seamless CNC machine tool operation. The frequency and duration of planned and unplanned downtime can be greatly reduced by using genuine, high quality Fanuc parts from a trusted supplier like Songwei. Here's how:

- Improved performance and longevity: Genuine Fanuc parts are designed to meet the highest quality and performance standards.

- Compatibility and Integration: Using Genuine Fanuc parts ensures full compatibility with existing equipment.

- Comprehensive testing and certification: Songwei components are subject to a comprehensive testing and certification process.

- Expert Maintenance and Support: Access to expert maintenance and support services is critical to preventing and resolving downtime problems, and Songwei offers specialized maintenance services performed by experienced technicians who are well versed in Fanuc systems.

- Upgrade and modernization: Upgrading and modernizing your equipment with the latest Fanuc parts can improve performance and reliability.

Conclusion

In conclusion, solving downtime problems requires measures that include preventive maintenance, quality parts and expert support to minimize downtime and optimize operations.

Reliable Fanuc parts and service are an integral part of solving downtime problems, and quality parts and expert maintenance services from Songwei ensure that your CNC machine tools operate at peak efficiency and minimize downtime. By partnering with a trusted supplier, you can improve the performance and longevity of your equipment, resulting in increased productivity and profitability.