How to Solve the Fanuc Servo 430 Alarm?

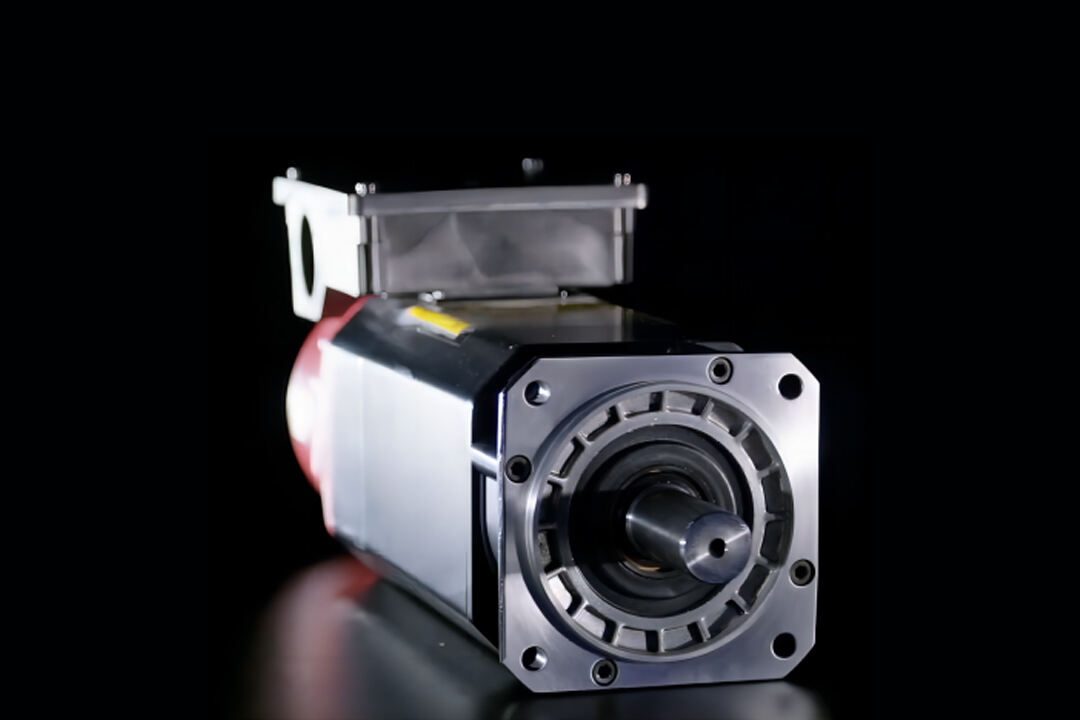

The Fanuc Servo 430 Alarm is a common error code that indicates a fault within the servo system. Typically, it indicates a problem associated with an overcurrent condition, which can occur when there is a problem with the servo motor, its power supply, or the servo drive. Ignoring or delaying resolution of a Servo 430 alarm can result in machine downtime, reduced productivity, and potential damage to the servo motor or related components. Timely troubleshooting and problem resolution are critical to prevent further complications and ensure that the machine continues to operate efficientl

Hvað er a Fanuc Servo 430 Alarm?

Definition and Cause: The Servo 430 alarm is triggered when the Fanuc system detects an overcurrent condition, usually caused by a problem in the servo motor or its control system. This alarm is intended to alert the operator that the motor current is exceeding safe operating limits. Overcurrents can be caused by a variety of reasons, including a faulty motor, faulty wiring, or a power supply problem.

Common Situations: The alarm usually occurs during high load operation, such as rapid movement or when the machine is running above its rated capacity. Problems such as a short-circuited motor, a faulty servo drive assembly, or insufficient power supply may also trigger an alarm.

Possible causes of Fanuc Servo 430 alarms

Overcurrent condition: An overcurrent occurs when a servo motor draws more current than the system is designed to handle. This can be caused by a faulty component such as an excessive motor load, sudden jerky motion, or a damaged motor winding.

Overload or Motor Failure: When a motor experiences mechanical wear, misalignment, or damage to the bearings or windings, this can lead to increased friction or strain, resulting in higher current draw.

Wiring Problems: Faulty wiring or poor connections can cause excessive current draw, which can trigger an alarm. Loose terminals, short circuits or damaged cables can cause wiring problems that can affect motor performance.

Servo Drive Problems: The servo drive itself can fail due to overheating, poor wiring, or internal component failure, resulting in abnormal current readings and triggering the 430 alarm.

Grunnskref úrræðaleitar

Skref 1: Check the Alarm Code The first step in troubleshooting is to confirm that the alarm code displayed is indeed 430 This can be done by referring to the Fanuc machine manual or control panel to ensure that the problem is servo related. If the alarm code is different, it may indicate another problem.

Skref 2: Shut down the machine, before checking any components be sure to power down the machine and disconnect it from the power source to ensure safety during troubleshooting.

Skref 3: Inspect the servo motor, visually inspect the servo motor for signs of physical damage such as burnt areas, discoloration, or broken wires. Check for signs of overheating or physical stress that may indicate motor failure.

Skref 4: Verify Wiring Connections Double-check all wiring connections between the servo motor, servo drive, and control system. Ensure that the wires are properly insulated, tightly connected, and free of any fraying or wear. Loose or damaged connections may result in electrical failure.

How to Clear the 430 Alarm

Reset the System: Once the potential cause of the alarm has been identified and resolved, the next step is to reset the system. Many Fanuc machines allow the user to reset alarms through the control panel. Typically, you can press the Reset button to clear the alarm code.

Using the Control Panel: On some machines, alarms can be cleared by navigating to the Diagnostics or Alarms section of the machine control panel. Follow the on-screen instructions to reset the alarm and verify that the machine can be returned to operation.

Verify operation after reset: After resetting the alarm, run a series of test cycles or small operations to verify that the problem has been completely resolved. Closely monitor the system for recurring alarms and ensure that the servomotor is operating within safe current limits.

Ítarlegri bilanaleit

Measure Motor Resistance: If the alarm persists after basic troubleshooting, it may be necessary to measure the resistance of the motor windings using a multimeter. A significant deviation from the expected resistance value indicates that there may be internal damage to the motor, such as a short circuit or a broken winding.

Check Servo Drive Settings: Incorrect settings of the servo drive can sometimes result in an overcurrent condition. Ensure that the drive is set up according to the motor's specifications, such as rated current and voltage, and verify that all parameters are properly configured for the machine load and operating conditions.

Test the encoder: If the servomotor uses an encoder to provide feedback to the control system, a faulty encoder can also cause false current readings and trigger an alarm. Test that the encoder is working correctly by checking the feedback signal and comparing it to the expected value.

Check the power supply: Check that the power supply is providing the correct voltage and is stable. A fluctuating or insufficient power supply can cause excessive motor current, which can trigger an alarm.

Hvenær á að hringja í fagmann

If basic troubleshooting steps do not resolve the alarm, it may be necessary to consult a professional technician who specializes in Fanuc systems. Professionals have the experience and tools needed to diagnose more complex problems, such as servo drive failures or deeper electrical issues.

At Songwei, we offer specialized repair and inspection services for Fanuc servo systems. Our team can help diagnose the exact cause of a Servo 430 alarm and provide a solution to return your system to peak performance. If you need help with troubleshooting, repair or testing services, hafðu samband við Songwei í dag.