Hogyan oldjuk meg a Fanuc rendszer riasztást 401-es hibakóddal?

Találtál már Fanuc Rendszerfigyelési Alkalmazást 401-es hibakóddal?

Ez a cikk olyan ismereteket ad, amelyek segítségével meghatározhatod az okokat, hatékonyan hibátlaníthatsz és megakadályozhatod újrafordulásukat. Függetlenül attól, hogy tapasztalt műszaki szakember vagy új Felhasználó a Fanuc-rendszerek terén, itt találhatók konkrét tanácsok annak biztosításához, hogy a műveleteid folyamatosan sikeresek legyenek.

Hogyan lehet hibakeresni a Fanuc Rendszer 401-es figyelmeztetést?

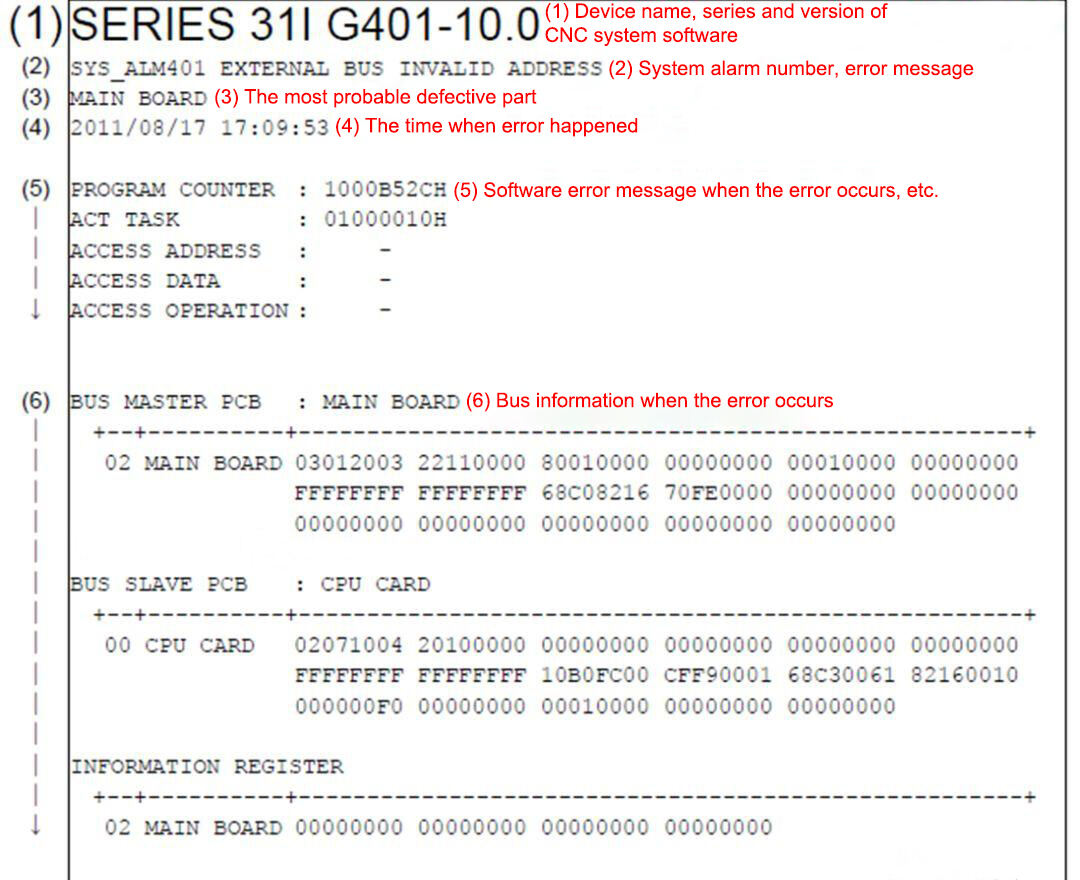

Amikor ezzel a figyelmeztetéssel találkozol, az egyértelműen látható a képernyőn, mint az alábbi képen látható módon:

A legvalószínűbb hibás rész a (3)-ban látható. Ellenőrizd a hibákat az adott terület körében.

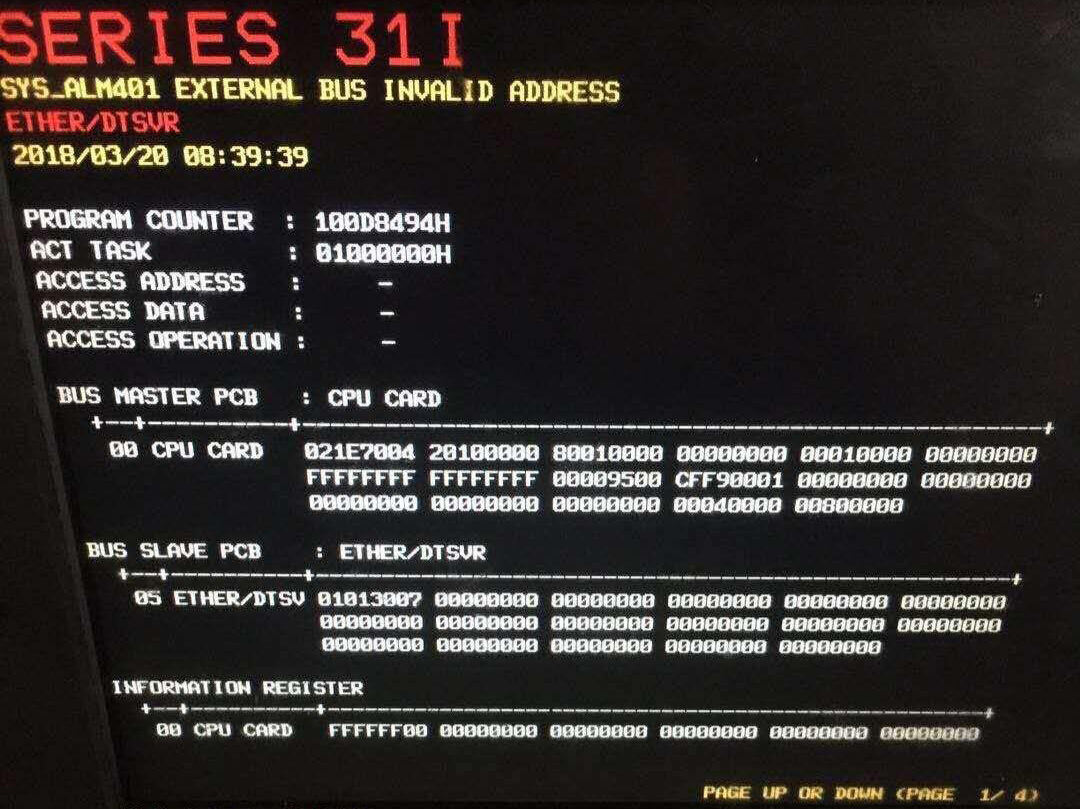

Az alábbi egy valós példa:

Rendszerfigyelési alkalmazás 401 (Érvénytelen külső busz cím)

Figyelmeztetés leírása:

Probléma történt a CNC buszon.

Okozó:

Lehetséges, hogy defektusos a nyomtatott körkészlet, vagy külső zaj hatással van rá.

Megoldás:

Cserélje ki azt a részt, amelyik a legvalószínűbb hibát okoz. Lehet, hogy alapter , a rendszer riasztókijelzőjén látható „MASTER PCB”, vagy a „SLAVE PCB” defektusos.

Emellett a hiba külső zajok miatt is előfordulhat.

Ellenőrizze, hogy nincs-e zajaforrás a gép közelében, és hogy helyesen van-e talajozva.

Előzáró intézkedések az 401-es riasztás elkerülésére

Bár fontos megoldani az 401-es riasztást, ennél értékesebb annak elkerülése, hogy folytonos működést biztosítson. Proaktív karbantartási megközelítéssel jelentősen csökkentheti a riasztás bekövetkezésének valószínűségét, és a Fanuc-rendszer maradandóan optimálisan fog működni.

Rendszeres karbantartási ellenőrzések:

Rendelje el rendszeresen a CNC-rendszerek ellenőrzését, hogy azonosítsa a potenciális problémákat, mielőtt aggasztóvá válnának. Koncentráljon a kritikus komponensekre, például a szervomotorokra, amplifikátorokra és áramellátásokra, hogy biztosítaniukért, hogy ezek pormentesek, szemétmentesek és fizikai kár nélkül működnek.

Győződjön meg arról, hogy a kapcsolatok szorosak:

A széteső vagy instabil kapcsolatok gyakori okai lehetnek az Alarm 401-es hibának. Ellenőrizze mindent időnként a kabeltörzsöket és csatlakozókat a szorúság szempontjából, különösen a gép nagyobb használata alatt vagy a rendszer beállításai után.

Tisztassa meg a rendszerkomponenseket:

A felhalmozódó sár és por zavarhatja az elektronikai komponensek megfelelő működését. Használja a megfelelő tisztítási módszereket a gútolók, hővezetések és ventillációs területek tisztaságának fenntartásához, hogy megakadályozza a túlmelegedést és az elektromos hibákat.

Rendszer paraméterek figyelése:

Tisztázzon meg a Fanuc-rendszer optimális beállításait, és figyelje ezeket a paramétereket rendszeresen. A jelentős eltérések hamarosan felmerülő problémákat jelezhetnek, amelyekre figyelmet kell fordítani az alarm aktív leszámítása előtt.

Ezen óvatosságok megvalósításával nemcsak csökkentheti a 401-es riasztás bekövetkezésének kockázatát, hanem növeli az egész életkort és hatékonyságát a Fanuc felszerelésének.

Összegzés

Ebben a cikkben megvizsgáltuk az Alarm 401 jelentését, az alapvető okait, a hibakeresési lépéseket és a megelőző stratégiákat a jövőbeli esetek elkerülése érdekében. Az alapvető ok megértésével és a karbantartás proaktív megközelítésével drasztikusan csökkentheti a leállási időt, és biztosíthatja, hogy a CNC rendszer maximális hatékonysággal működjön.

A Songwei-nél elkötelezettek vagyunk arra, hogy teljes körű szolgáltatásokkal támogassuk Fanuc automatizációs igényeit, beleértve az új és átdolgozott termékeket, a szakértői javításokat és a fejlett tesztelési megoldásokat. Függetlenül attól, hogy riasztási problémával küzd, vagy szakértői tanácsot keres a rendszer optimalizálásához, a csapatunk mindig segítségére kész. Forduljon ma még el a Songweire további információkért vagy segítség kérése érdekében!