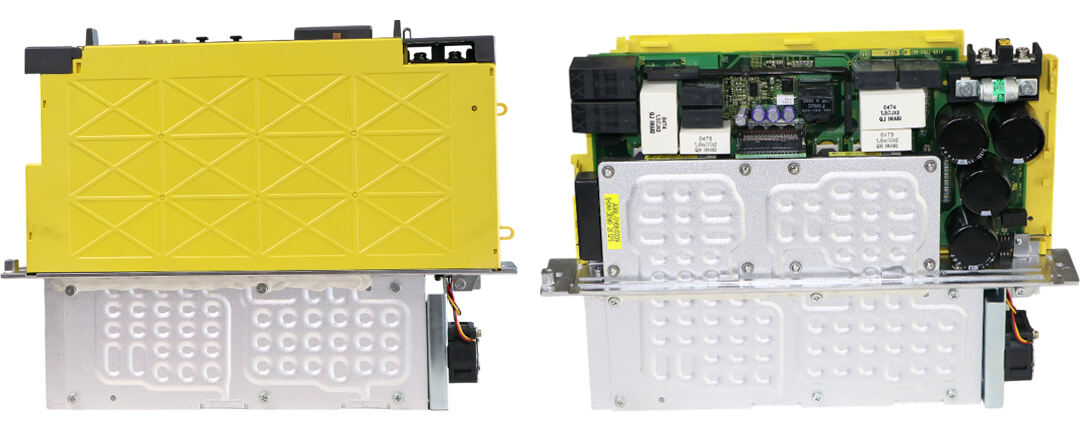

Ag Lascadh uaireanta: na n-Inniúchtaí Inmheánacha den Fhréamh Servo Fanuc

Tá fadhbálaí Fanuc ina chuid is gairid den phróiseas nua-aimseartha agus de na mhinicíní CNC. Díríonn na fadhbálaí seo ordúcháin i gcás moill ann go díríonn sé go soiléir ar an gcuardach a bheith ag oibrigh le fiúntas uillean agus le hiomparacht. Mar ghearrthréad sa réimse faoi láthair, tá na fadhbálaí Fanuc ina luachanna mar gheall ar a n-ábharas agus ar a theicneolaíocht chrua, ag cinntiú go bhfuil siad rogha tosaigh don mhatamánach. An ndéanann tú cinnte conas oibríonn na fadhbálaí Fanuc?

Rith Fadhbálaí Fanuc

Tá fadhbálaí speisialta ag obair le haghaidh rialú na n-imeartha motor. Glac siad faoi ordúcháin agus traslódóidís i gcás moill shonracha, ag tabhairt aisghníme do chomhrádacht. Úsáidtear comhrádh chontinuítíochta ag na fadhbálaí chun cuardach sonrach agus glan a chur i bhfeidhm. Mar sin féin, tá na fadhbálaí seo ceart-suisiútha don úsáid atá ag teastáil as fíor-mhioladh agus seans dinimiciúil.

1. Struchtúr Inmheánach Fanuc Fadhbálaí

Bord Cirtseála : Próiseáiltear ordúcháin isteach ag an bhord seolta CNC agus cruthaíonn sé comhcheangal idir na n-orduithe sin chun liathróidí a rialú.

Aeráid Feadbach : Glactar le feabhsú an phost agus an spéir de chineál na mótora trí bhainistiú ós cionn na gcodanna agus na ndíbhriathra feadbach chun cinntiú go bhfuil an chóras in ann cáipéisí i réaltaimh a dhéanamh.

Tugann an comhréir fuaimeach idir an fhoithne, an chóras rialaithe agus an aeráid feadbach do Shheirbhísí Fanuc a bheith in ann tuairimí earraíochta a chur ar fáil san ábhar bródúil.

2. Conas Oibríonn Drives Seirbhís

Cur síos ar Rialú I gCiorcal Dúnaithe: Oibríonn drives seirbhís Fanuc i gcóras rialaithe i gcuirc dúnaithe, faoi láthair glactar le feabhsú agus spéir na mótora trí mhéid feadbach.

Conas a gcuiretar ordúcháin isteach agus a phróiseáiltear: Téitear ordúcháin ón bhfoithne CNC chuig siompónaí tríd a dtógfar comhaid siol-eilectreach a thugann léiriú don shrive seirbhís conas a théifidh liathróid.

Ról na Níoracháin i gCúlú Móidithe: Tá scileanna íorachta ag tuar scéal faoi phost chaite an mhothaireach chun go mbeadh cáilghearrthu ar fad i gcónaí chun cúram a thabhairt don chosaint.

3. Algoritmiúl agus Cumarsáid a úsáidtear i n-Íorchur Fanuc

Tá Íorchur Fanuc ag úsáid beartán éagsúla, mar shampla Rialtóireacht Chomhfhada-Iontach-Difriúil (PID) chun cúplach móidithe a chur isteach.

Is féidir le hathrú cothromach seo earráidí a laghdú, dul síos ar shuighneacha agus freastal ar fhuascailteacht an chórais go léir.Fanuc servo drives úsáidtear beartán éagsúla cumarsáide, mar shampla CANopen agus EtherCAT , chun cabhrú le díospóireacht sonraí idir na ndráiví agus rialatóirí CNC. Is féidir leis na prótacail seo cumarsáid luaithe a chur i bhfeidhm, chun go mbeadh an dráiv íorchur in ann freagairt go hiomlán do athruithe sa chás oibriúcháin.

Féiniúlacht Fanuc Servo Drives

Úsáidtear druaí serva Fanuc i gcríocha éagsúla, a chomhlódhann an macrún, an speisialéireacht agus an bonnaitheacht leictreonach. Is iad scileanna uilig i gcónaí i róibheach, CNC milting agus próiseasacha eile fosta.

Buntáistí ó úsáid Druaí Serva Fanuc: Tá na draoí seo ar fad luachmhar i mbeartaithe bonnaitheacht láithreach mar thoradh orthu glacadh le hiompórtuitheacht, fíorú níos fearr agus meán ama cúpla amharc.

Críoch

Tá tuiscint iomlán ar chomhthionndódh a rinneann na draoí serva Fanuc go soiléir faoi choinneál cainte chun do chóras CNC a chur chun tosaigh agus chun oibríocht slasta a chinntiú. Má tá ioncam agat nuair a bhfuil tú ag cinntiú do chórais Fanuc is féidir leat comhrac le héan-éigeandál chun tacaíocht pearsantach a fháil chun feabhsú saor in aisce agus cumas.