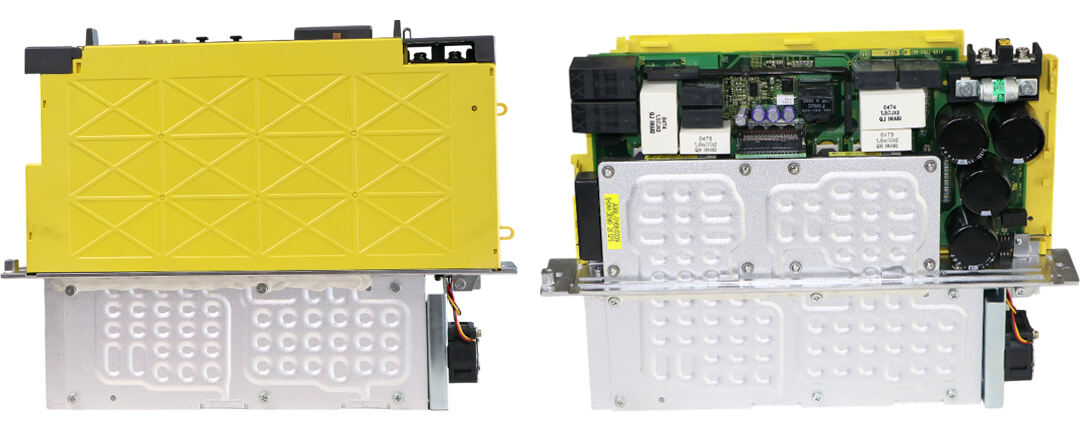

Opdag Nøjagtighed: De Indre Arbejder af en Fanuc Servo Drive

Fanuc servo drives er en vigtig del af moderne automatisering og CNC-maskineri. Disse drives omformer kommandoer til nøjagtige bevægelser, hvilket sikrer, at maskinerne fungerer med høj præcision og effektivitet. Som en førende mærkevare inden for industrielt automatiseringsområde er Fanucs servo drives kendt for deres pålidelighed og avancerede teknologi, hvilket gør dem til den naturlige valg for mange producenter. Forstår du så, hvordan Fanuc drives fungerer?

Fanuc servo drive operation

Servo drives er specialiserede elektroniske enheder, der kontrollerer motorens bevægelse. De modtager inputkommandoer og oversætter dem til nøjagtige motorbevægelser, samtidig med at de giver feedback for at sikre nøjagtighed. Servo drives bruger kontinuerlig feedback for at opnå smooth og præcise bevægelser. Derfor er servo drives ideelle til anvendelser, der kræver høj præcision og dynamisk ydelse.

1. Indre Struktur af Fanuc Servo Drives

Styrkredsløb: Behandler indgående kommandoer fra CNC-kontrolleren og fortolker disse kommandoer for at regulere motorbevægelser.

Feedbackelement: Overvåger motorens position og hastighed ved hjælp af encodere og sensorer for at sikre, at systemet kan foretage reeltidsjusteringer.

Den smukke samspil mellem strømforsyningen, styringskredsløbet og feedbackelementet gør det muligt for Fanuc servo-drivere at levere fremragende ydeevne i krævende anvendelser.

2. Hvordan servo-drivere fungerer

Beskrivelse af lukket-løb kontrol: Fanuc servo-drivere fungerer på et lukket-løb kontrolsystem, hvor drivet kontinuerligt overvåger motorens position og hastighed gennem en feedbackmekanisme.

Hvordan kommandoer modtages og behandles: Kommandoer fra CNC-kontrolleren konverteres til elektriske signaler, der instruerer servo-drivet om, hvordan motoren skal bevæges.

Rollen af feedback i opnåelse af nøjagtig bevægelse: Feedback-enheder rapporterer konstant den faktiske position af motoren til styringscirkusserne, så at justeringer kan foretages i realtid for at opretholde nøjagtighed.

3. Styringsalgoritmer og kommunikation brugt i Fanuc servo-styrene

Fanuc servo-styrene anvender en række styringsalgoritmer, såsom Proportional-Integral-Differential (PID)-styring, for at sikre præcis bevægelse.

At korrekt justere disse parametre minimerer fejl, reducerer overkørsel og forbedrer systemets generelle responsivitet. Fanuc servo-styrene anvender en række kommunikationsprotokoller, såsom CANopen og Ethercat , for at lette udvekslingen af data mellem styrene og CNC-kontrollere. Disse protokoller gør det muligt at kommunikere hurtigt, hvilket tillader at servo-styret kan reagere øjeblikkeligt på ændringer i driftsforholdene.

Fanuc Servo Styre Anvendelser

Fanuc servo-drivere bruges i en bred vifte af industrier, herunder bil-, luftfart og elektronikproduktion. De er uundværlige i robotik, CNC-fræsning og andre automatiserede processer.

Fordele ved at bruge Fanuc Servo Drivere: Disse drivere er højst værdifulde i moderne produktionsmiljøer, fordi de øger produktiviteten, forbedrer nøjagtigheden og reducerer nedetid.

Konklusion

En grundig forståelse af, hvordan Fanuc servo-drivere fungerer, betyder meget for at optimere din CNC-system og sikre en smooth drift. Hvis du har behov for at optimere dit Fanuc-system, er du velkommen til at konsultere en ekspert for personaliseret support for at sikre langsigtet succes og produktivitet.