7 стъпки за поддържане на моторите си Fanuc в най-добър вид!

Регуларната поддръжка е критична за живота и перформанса на моторите Fanuc. Чрез влагането на време в рутинната поддръжка, можете да подобрите ефективността, да намалите неплановеното спирание и да гарантирате надеждно функциониране. Тази статия предоставя основни съвети, които ще ви помогнат да поддържате успешно моторите си Fanuc.

Разбиране на моторите ви Fanuc

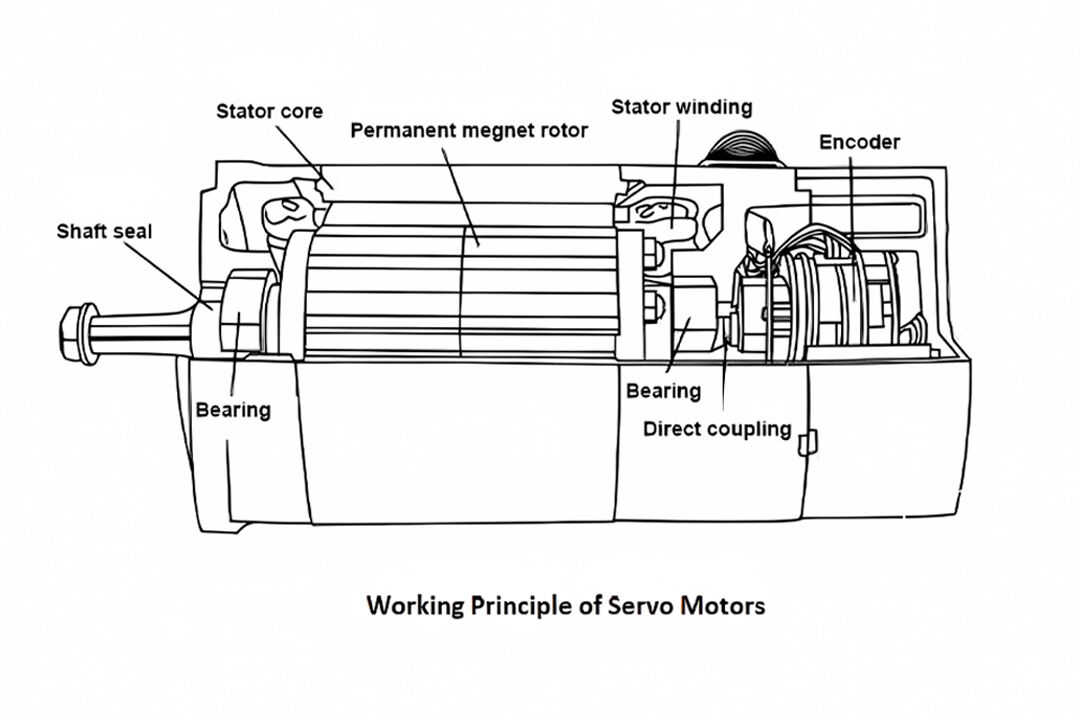

Fanuc предлага разнообразие от видове мотори, включително АС, ДС и сервомотори. Всеки вид има уникални характеристики и приложения. Ключови компоненти на типичен мотор включват статор, ротор и енкодер. За да поддържате по-добре мотора си, разберете каква е ролята на всеки компонент за общия перформанс на мотора.

Как да поддържате мотора си

1. Разработете програма за поддръжка

Разработете график за поддръжка, който идентифицира колко често трябва да се извършва всяка задача за поддръжка - дневно, седмично, месечно или тримесечно. Използвайте списъци с отметки, за да се уверите, че всички необходими задачи като проверки, усмълване и тестове са завършени, което прави по-лесно проследяването на състоянието на вашия мотор.

2. Очистване на мотори Fanuc

Прахът и други отпадъци могат да намаленият производителността на мотора. Регулно очистване помага да се предотврати прелагането и изнасянето. Използвайте компресиран въздух и мека щетка, за да премахнете леко праха от външните и вътрешните компоненти. Избягвайте използването на агресивни химикали, които могат да повредят чувствителните части, за да се осигури безопасен и ефективен процес на очистване.

3. Проверка и замяна на подшипници

Проверете за признаци на изнасяне, включително необикновен шум, вибрация или прелагане. Регулно проверяйте подшипниците за признаци на повреда и заменяйте ги, когато е необходимо, за да се поддържа оптималната производителност. За замяната на подшипниците на мотора за вала Fanuc може да се отнесе до следното:

- Подшипници на спиралния мотор са прецизни детайли, а силата за демонтаж не трябва да действа директно върху топките на подшипника или върху външното кръгло, т.е., при демонтаж и монтаж на подшипниците на спиралата, силата трябва да действа върху вътрешното кръgło на подшипника, за да не се намали прецизността на подшипниците и да не се повлияе върху техния ресурс.

- При монтаж на подшипници, ъглово-контактните подшипници трябва да гарантират, че конфигурацията при монтаж и демонтаж е една и съща (бележка: единият край на вътрешното или външното кръgło на подшипника е по-широк, другият е по-свивест, не ги инсталирайте грешно, защото това може да причини разделение на вътрешното и външното кръгло, радиален отклонение на спиралата и лесно повредяване на подшипниците).

- Редовна замяна на мотора на спиралата Мазнини , смазка специална високоскоростна литиева смазка.

- При работа на спиндловия мотор, ако се откриват необичайни звуци или вибрации, трябва да се спре и да се проверят подшипниците за повреда. Ако е необходимо, заменете ги с нови подшипници. При появата на необичайни миризи по време на операцията или при спиране, изключете напояването. Измерете супротивността на статорния кръг чрез вмъкване на мегаватерметър. Ако супротивността е 0, това означава, че е изгорял и трябва да се замени статорната завойка.

- Мие се подшипниците за първи път с 93 # стандартно замачване през 15 минути, след което се измиват с щетка. При всяко прилагане трябва да се извършват поне три промива с чиста вода. Строго забранено е да се въртят без предварително промиване. След това те трябва да се насушат и да се добави литиево смазно масло висока скорост. Количество на смазното масло трябва да бъде около 20% - 50% от пространството на подшипника.

4. Проверка на електрическите свързания

Периодично проверяйте всички свързания за знаци на корозия, износ или разтягане. Затворете всички разтянати свързания и премахнете корозията с подходящ електричен контактен чистач.

5. Мониторинг на температурата на мотора

Флуктуациите на температурата могат сериозно да повлияят върху производителността на мотора. Използвайте термичен сензор, за да следите регулярно работната температура на мотора. Гарантирайте, че системата за охлаждане функционира правилно, за да се предотврати прегреването. Ако температурите надминат препоръчителните нива, проучете възможните причини и предприемете коригиращи мерки.

6. Мерки за смазване

Правилното смазване намалява триенето и износът на моторите Fanuc. Използвайте смазното средство, препоръчано от производителя, и следвайте правилното му прилагане. Избягвайте прекомерно смазване, което привлича гряз и води до допълнителен износ. Разработете програма за смазване, за да проследявате кога и къде е приложено смазването.

7. Тестване на мотора Перформанс

Рутинните тестове за производителност могат да открыват проблеми преди да се усилат. Провеждайте тестове като анализ на вибрацията, електрически тестове и тестове под товар, за да оцените функционирането на мотора. Записвайте резултатите от тестовете и проследявайте тенденциите в производителността с течение на времето, за да идентифицирате потенциални проблеми на ранен етап.

Заключение

Подводейки, поддържането на мотори Fanuc е критично за гарантиране на техния ефективност и надеждност. Чрез прилагане на проактивна стратегия за поддържане и следване на съветите, описани в тази статия, можете да продължите живота на моторите си и да подобрите общата операционна производителност. Използвайте тези методи, за да получите най-добри резултати и да минимизирате скъпостойното спираne. За експертна помощ при поддържането или ремонта, не се колебайте да се свържете Нашият екип в Songwei!